Introduction to Electronic Manufacturing Services (EMS)

In today’s interconnected world, electronic devices are ubiquitous, powering everything from our smartphones to complex industrial machinery. Behind the scenes of this technological revolution lies the intricate process of electronic manufacturing. For many companies, managing this complex undertaking in-house is resource-intensive and challenging. This is where Electronic Manufacturing Services (EMS) providers step in, offering specialized expertise and streamlined solutions for bringing electronic products to life. This article serves as your comprehensive introduction to the world of EMS, exploring its importance, evolution, and the core benefits it offers.

What are Electronic Manufacturing Services (EMS)?

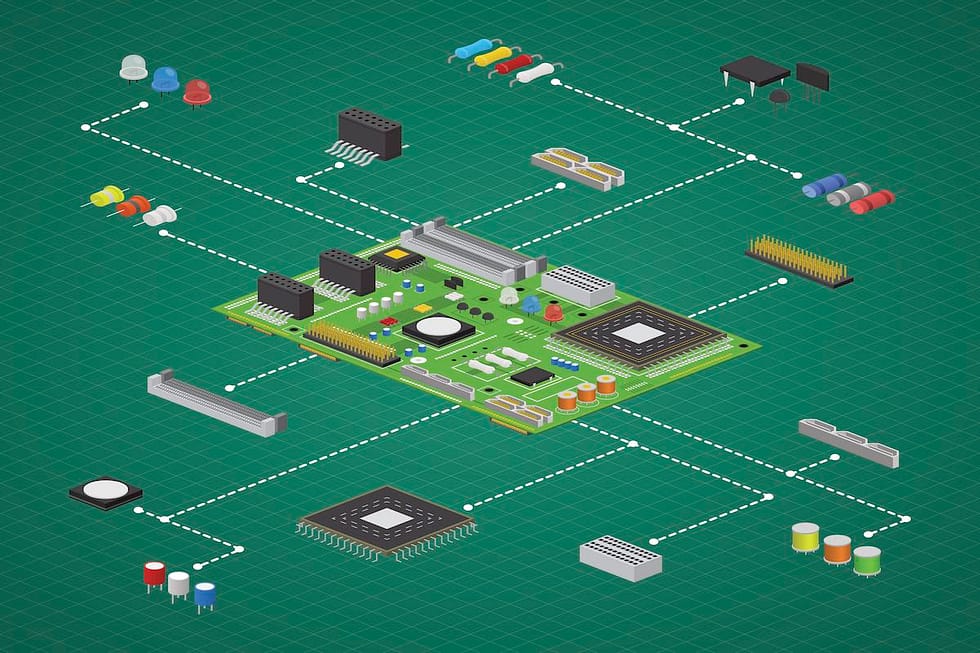

Electronic Manufacturing Services (EMS) companies are your one-stop shop for outsourcing the manufacturing, assembly, and testing of electronic components and finished products. They act as a strategic partner, taking on the often-complex task of bringing your electronic designs from concept to reality. Think of them as the specialized factories and expert teams that handle everything from sourcing components to assembling intricate circuit boards and packaging the final product, allowing you to focus on your core competencies like product design and marketing.

Electronic Products

Why are EMS Important?

In a world of ever-shortening product lifecycles and increasing technological complexity, EMS providers offer crucial advantages.

- Cost-Effectiveness: EMS providers leverage economies of scale, bulk purchasing power, and optimized manufacturing processes to reduce production costs. They also eliminate the need for companies to invest heavily in manufacturing facilities and equipment.

- Expertise and Specialization: EMS companies possess deep expertise in electronic manufacturing, including printed circuit board (PCB) assembly, component sourcing, testing, and quality control. They stay at the forefront of industry advancements and best practices.

- Flexibility and Scalability: EMS providers offer flexible manufacturing capacity, allowing companies to scale production up or down quickly to meet changing market demands. This agility is crucial in today’s dynamic business environment.

- Focus on Core Competencies: By outsourcing manufacturing to an EMS provider, companies can free up valuable resources and focus on their core strengths, such as product design, research and development, and marketing.

- Reduced Time to Market: EMS providers can accelerate the product development and manufacturing process, helping companies bring their products to market faster and gain a competitive edge.

- Access to Latest Technologies: EMS providers are constantly updating their technology and equipment to keep pace with the rapidly evolving electronics industry. This access allows their clients to benefit from the latest manufacturing processes without massive capital outlay.

A Brief History of EMS

The EMS industry has evolved significantly over the past few decades. Initially, it focused primarily on simple assembly tasks. However, as technology advanced and manufacturing processes became more complex, EMS providers expanded their service offerings to include design support, component sourcing, testing, and logistics. The rise of globalization and the increasing demand for outsourcing further fueled the growth of the EMS industry. Read more about the history of EMS here.

The Value Proposition of EMS

The core value proposition of EMS lies in its ability to provide a comprehensive and integrated solution for electronic product manufacturing. By partnering with an EMS provider, companies can:

- Reduce costs and improve profitability.

- Access specialized expertise and cutting-edge technology.

- Increase flexibility and scalability.

- Focus on core competencies and accelerate time to market.

- Improve product quality and reliability.

- Gain a competitive advantage in the global marketplace..

Conclusion

Electronic Manufacturing Services have become an indispensable part of the global electronics industry. By outsourcing manufacturing to a trusted EMS partner, companies can unlock significant benefits, from cost savings and improved efficiency to increased flexibility and faster time to market. As technology continues to advance and market dynamics evolve, EMS providers will play an even more critical role in helping companies bring innovative electronic products to life. In the next sections of this cornerstone article, we’ll delve deeper into the specific services offered by EMS providers and explore the key factors to consider when choosing the right partner for your needs.

Core Services Offered by Electronic Manufacturing Services (EMS) Providers

In the previous section, we explored the importance of Electronic Manufacturing Services (EMS) and their role in the electronics industry. Now, let’s dive into the core services offered by these providers, giving you a comprehensive understanding of what they can do for your business. From initial design support to final product assembly and even after-sales service, EMS providers offer a wide array of capabilities.

1.Manufacturing & Assembly: The Heart of EMS

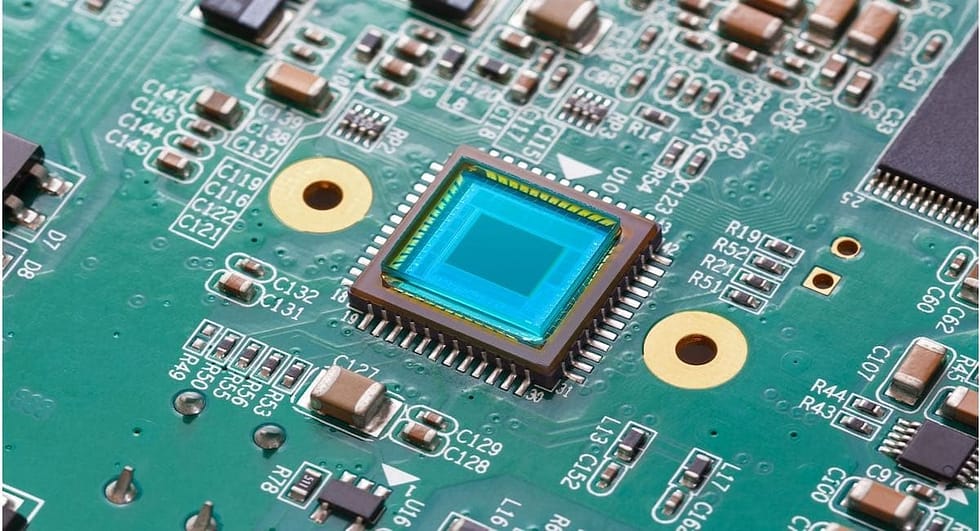

- Printed Circuit Board (PCB) Assembly: This is arguably the most fundamental service. EMS providers are experts in assembling electronic components onto PCBs using various techniques:

- Surface Mount Technology (SMT): For small, surface-mounted components, offering high density and miniaturization. EMS providers utilize sophisticated pick-and-place machines and reflow ovens for precise and efficient SMT assembly.

- Through-Hole Technology: For larger, leaded components, often used in applications requiring greater durability. This involves inserting component leads through holes in the PCB and soldering them on the other side.

- Mixed Technology: Combining both SMT and through-hole assembly on a single board to optimize for component size, cost, and reliability.

Read our blog on PCB Assembly Process Explained to learn the details.

- Cable and Harness Assembly: EMS providers fabricate and assemble cable harnesses, which are essential for connecting different parts of electronic systems. This includes cutting, stripping, crimping, and terminating wires, as well as assembling connectors and other hardware.

- Box Build and System Integration: This involves assembling various components, including PCBs, cables, power supplies, and enclosures, into a complete unit. EMS providers handle everything from mechanical assembly and wiring to software loading and system testing.

- Electromechanical Assembly: This combines electronic components with mechanical parts, such as motors, gears, and switches. EMS providers possess the expertise to integrate these elements seamlessly into a functional product.

- Final Product Assembly and Testing: The culmination of the manufacturing process, this involves assembling all the sub-components into the final product, packaging it, and conducting final testing to ensure functionality and quality.

2. Design & Engineering Support: Beyond Manufacturing

Many EMS providers offer design and engineering support services, adding value beyond simply assembling components. These services can include:

- Design for Manufacturing (DFM) and Design for Assembly (DFA): These crucial processes ensure that the product design is optimized for efficient and cost-effective manufacturing. DFM focuses on simplifying the manufacturing process, while DFA focuses on making the product easy to assemble. Watch this video to learn more.

- Prototyping and New Product Introduction (NPI): EMS providers assist with prototyping and NPI, helping companies bring their new products to market quickly. This includes rapid prototyping, pilot production runs, and design validation. Read our detailed blog on How an EMS can supercharge your PCB Prototyping.

- Engineering Change Orders (ECOs) and Product Lifecycle Management: EMS providers manage ECOs, implementing design changes and updates throughout the product lifecycle. They also assist with product lifecycle management, ensuring that products are manufactured and supported throughout their lifespan.

- Test Engineering and Development: Developing and implementing test strategies is critical to ensuring product quality. EMS providers design and build test fixtures, develop test software, and perform various types of testing, including functional testing and in-circuit testing.

3. Component Sourcing & Procurement: A Critical Link in the Chain

Effective component sourcing and procurement are essential to the success of any electronic product.

EMS providers offer:

- Global Sourcing and Supply Chain Management: EMS companies have established networks of suppliers around the world, enabling them to source components at competitive prices. They manage the entire supply chain, from supplier selection and qualification to procurement and logistics.

- Inventory Management and Control: EMS providers can manage inventory levels, ensuring that components are available when needed while minimizing inventory holding costs. They use sophisticated inventory management systems to track component usage and forecast demand.

- Component Engineering and Obsolescence Management: EMS providers can assist with component selection, ensuring that the right components are used for the application. They also manage component obsolescence, identifying and replacing obsolete components to ensure long-term product availability.

4. Testing & Quality Control: Ensuring Excellence

Quality is paramount in the electronics industry. EMS providers employ a variety of testing and quality control measures:

- Automated Optical Inspection (AOI): AOI systems use cameras to inspect PCBs for defects, such as missing components, incorrect placement, and solder bridges.

- In-Circuit Testing (ICT): ICT uses probes to test the electrical connectivity of components on the PCB, identifying shorts, opens, and other faults.

- Functional Testing: Functional testing verifies that the product performs its intended function. This may involve running software, simulating real-world conditions, and measuring performance parameters.

- Quality Management Systems (ISO 9001, etc.): Reputable EMS providers adhere to international quality standards, such as ISO 9001, demonstrating their commitment to quality and continuous improvement. Learn more about ISO standards here.

Read our blog on Quality Testing for Prototypes.

5. Logistics & Fulfillment: Getting Products to Market

The final stage of the manufacturing process involves getting the finished products to market. EMS providers offer:

- Warehousing and Distribution: EMS companies can provide warehousing and distribution services, storing finished products and shipping them to customers.

- Order Fulfillment and Drop Shipping: EMS providers can handle order fulfillment, including picking, packing, and shipping orders directly to customers. They can also offer drop shipping services, where products are shipped directly from the manufacturing facility to the end customer.

- After-Sales Support and Repair Services: Some EMS providers offer after-sales support and repair services, providing technical assistance and repairing defective products.

Conclusion

The comprehensive suite of services offered by EMS providers empowers companies to streamline their electronics manufacturing process, reduce costs, and focus on their core competencies. From design and engineering to manufacturing, testing, and logistics, EMS providers act as a strategic partner, helping bring innovative electronic products to life. In the following sections, we will discuss how to choose the right EMS partner for your specific needs and explore the latest trends shaping the EMS industry.

EMS for Different Industries: Tailored Solutions for Diverse Needs

Electronic Manufacturing Services (EMS) providers play a crucial role across a wide spectrum of industries, each with its unique requirements and challenges. From the stringent quality standards of medical devices to the ruggedness demanded by aerospace applications, EMS providers adapt their expertise and processes to meet the specific needs of diverse sectors.

Aerospace and Defense: Mission-Critical Reliability

- High-Reliability Components: Aerospace and defense applications often require components that can withstand extreme temperatures, vibration, and shock. EMS providers must have expertise in sourcing and handling these specialized components.

- Traceability and Documentation: Meticulous traceability and documentation are essential for ensuring the quality and reliability of aerospace and defense products. EMS providers must have robust systems in place to track every component and process.

- Long Product Lifecycles: Aerospace and defense products often have long lifecycles, requiring EMS providers to manage component obsolescence and ensure long-term product availability.

- Ruggedization and Environmental Testing: Products must be designed to withstand harsh environments. EMS providers conduct rigorous environmental testing, including temperature cycling, humidity testing, and vibration testin

Automotive: Meeting Stringent Automotive Standards

The automotive industry presents its own set of challenges, including high production volumes, strict quality requirements (e.g., IATF 16949), and demanding environmental conditions. Recently we were engaging with a popular luxury EV company in America. Their quality requirements are extremely stringent as they have to provide warranties to their customers to adhere to the laws. EMS providers serving this sector must:

- Automated Manufacturing: High production volumes require highly automated manufacturing processes to ensure efficiency and consistency.

- Zero-Defect Quality: The automotive industry demands near-perfect quality. EMS providers must have robust quality control systems in place to minimize defects.

- Environmental Robustness: Automotive electronics must withstand extreme temperatures, vibration, and humidity. EMS providers must use appropriate materials and processes to ensure reliability.

- Supply Chain Management: The automotive supply chain is complex and global. EMS providers must have expertise in managing this complex supply chain and ensuring timely delivery of components.

Consumer Electronics: Balancing Cost and Innovation

The consumer electronics industry is characterized by rapid innovation, short product lifecycles, and intense price competition. EMS providers serving this sector must:

- Cost-Effectiveness: Consumer electronics manufacturers are constantly looking for ways to reduce costs. EMS providers must offer competitive pricing and efficient manufacturing processes.

- Rapid Prototyping and NPI: The consumer electronics market moves quickly. EMS providers must be able to rapidly prototype and introduce new products to market.

- High-Volume Manufacturing: Consumer electronics products are often manufactured in very high volumes. EMS providers must have the capacity to handle these large volumes.

- Miniaturization and Advanced Packaging: Consumer electronics products are becoming smaller and more complex. EMS providers must have expertise in miniaturization and advanced packaging technologies.

Industrial Automation: Reliability in Harsh Environments

Industrial automation products often operate in harsh environments and require high reliability. EMS providers serving this sector must:

- Ruggedization and Durability: Industrial automation products must be designed to withstand extreme temperatures, vibration, and other harsh conditions.

- Long Product Lifecycles: Industrial automation products often have long lifecycles, requiring EMS providers to manage component obsolescence and ensure long-term product availability.

- Specialized Testing: Industrial automation products may require specialized testing to ensure that they meet specific performance requirements.

- Safety and Compliance: Many industrial automation products must comply with strict safety regulations.

Medical Devices: Uncompromising Quality and Regulatory Compliance

The medical device industry is subject to stringent regulatory requirements (e.g., FDA regulations) and demands the highest levels of quality and reliability. EMS providers serving this sector must:

- Regulatory Compliance: EMS providers must comply with all relevant regulations, including FDA regulations for medical devices.

- Quality Management Systems: Robust quality management systems are essential for ensuring the safety and efficacy of medical devices.

- Traceability and Documentation: Meticulous traceability and documentation are required for medical devices.

- Sterilization and Biocompatibility: Some medical devices require sterilization or biocompatible materials. EMS providers must have expertise in these areas.

Telecommunications: High-Speed and High-Frequency Expertise

The telecommunications industry requires expertise in high-speed and high-frequency electronics. EMS providers serving this sector must:

- High-Speed PCB Design and Assembly: Telecommunications equipment often requires high-speed PCB design and assembly to ensure signal integrity.

- RF and Microwave Expertise: Many telecommunications products involve RF and microwave technologies. EMS providers must have expertise in these areas.

- Testing and Validation: Thorough testing and validation are essential for ensuring the performance and reliability of telecommunications equipment.

- Network Infrastructure: EMS providers may be involved in the manufacturing of network infrastructure equipment, such as routers and switches.

Other Industries

Beyond these key sectors, EMS providers also serve a multitude of other industries, including:

- Energy: Manufacturing electronics for renewable energy systems and smart grids.

- Security: Producing electronic components for security systems and surveillance equipment.

- Transportation: Building electronics for trains, ships, and other transportation systems.

Conclusion

The adaptability of EMS providers is a key factor in their success. By tailoring their services and expertise to the specific needs of each industry, they enable companies to focus on their core competencies while trusting their manufacturing to a specialized partner. Whether it’s the stringent quality requirements of medical devices or the cost pressures of consumer electronics, EMS providers offer valuable solutions across the industrial landscape.

Choosing the Right EMS Provider: A Comprehensive Guide

Selecting the right Electronic Manufacturing Services (EMS) partner is a critical decision that can significantly impact the success of your electronic product. A strong partnership can lead to cost savings, faster time to market, and improved product quality. Conversely, a poor choice can result in delays, cost overruns, and even damage to your brand reputation. This comprehensive guide outlines the key factors to consider when choosing an EMS provider, empowering you to make an informed decision.

1. Defining Your Needs: The Foundation of Your Search

Before you start contacting EMS providers, it’s crucial to clearly define your specific needs and requirements. This will help you narrow your search and ensure that you’re targeting providers that are a good fit for your business. Consider the following:

2. Key Factors to Consider When Evaluating EMS Providers

Once you have a clear understanding of your needs, you can begin evaluating potential EMS providers. Here are the key factors to consider:

3. Due Diligence and Vendor Selection Best Practices

- Request for Information (RFI): Start by sending RFIs to potential providers to gather information about their capabilities and services.

- Request for Quote (RFQ): Once you’ve narrowed your list, send RFQs to get detailed pricing and lead times for your project.

- Site Visits: Visit the facilities of your top contenders to assess their manufacturing capabilities, quality control processes, and overall operations.

- Technical Discussions: Schedule technical discussions with the provider’s engineering team to discuss your product in detail and ensure that they have the necessary expertise.

- Contract Negotiation: Carefully review the contract terms and conditions before signing. Make sure that all aspects of the agreement are clear and mutually agreeable.

4. Building a Strong Partnership

Choosing an EMS provider is not just a transaction; it’s the beginning of a long-term partnership. Here are some tips for building a strong relationship with your chosen provider:

- Open Communication: Maintain open and regular communication with your provider to ensure that you’re aligned on project goals and timelines.

- Collaboration: Work collaboratively with your provider to solve problems and improve processes.

- Mutual Respect: Treat your provider as a valued partner and respect their expertise.

- Long-Term Vision: Focus on building a long-term relationship with your provider, rather than just focusing on short-term cost savings.

Conclusion

Choosing the right EMS provider is a complex but crucial process. By carefully considering the factors outlined in this guide and conducting thorough due diligence, you can find a partner that will help you bring your electronic products to market successfully. Remember that the best EMS provider is not necessarily the cheapest, but rather the one that best meets your specific needs and offers the best overall value.