Introduction

In an era where environmental consciousness is no longer an option but a necessity, industries worldwide are pivoting towards sustainable practices. Among these, manufacturing stands as a crucial frontier for change. Sustainable manufacturing is not just a buzzword; it’s a commitment to reducing ecological footprints while maintaining economic viability. In this blog, we delve into the significance of sustainable manufacturing and explore some noteworthy examples that illustrate its transformative power.

Climate change Is at the forefront of news as we have more information and world has become more connected than ever before. Goods flow across borders and cultures are changing rapidly. People everywhere want more manufactured goods. Manufacturing has increased everywhere to meet the demand. But it is not always done with consideration to the environment.

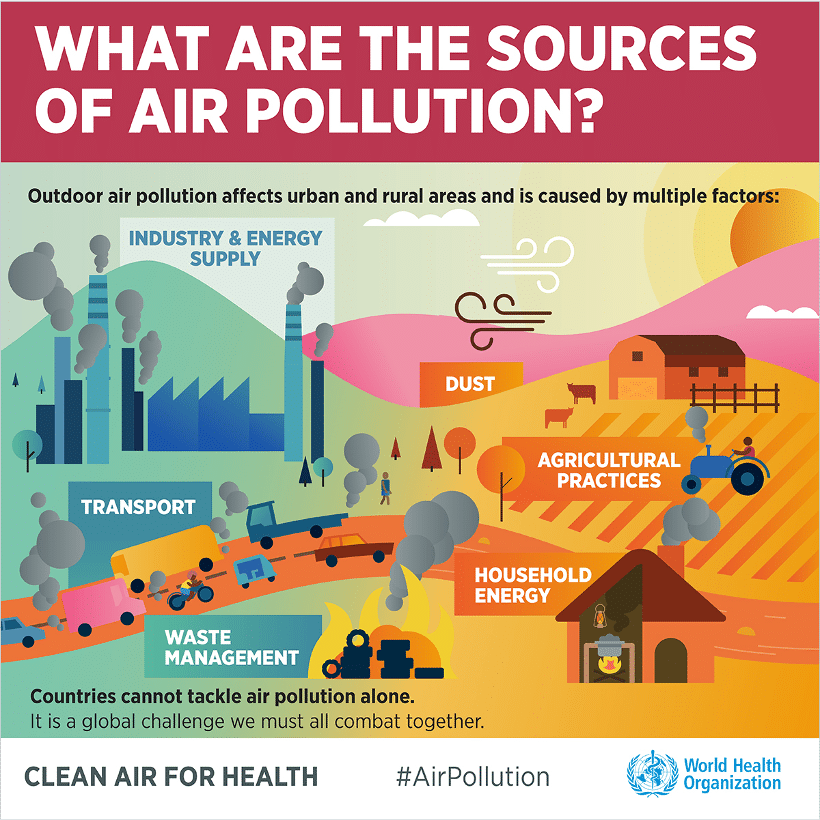

Manufacturing industries decrease air quality by releasing hydrocarbons, carbon monoxide, organic compounds and other chemicals into the air.

Sustainable manufacturing considers the environment and the social welfare of the community it serves while still focusing on growth and profit.

Understanding Sustainable Manufacturing

As per the Environmental Protection Agency (EPA) of the United States of America

“Sustainable manufacturing is the creation of manufactured products through economically-sound processes that minimize negative environmental impacts while conserving energy and natural resources.”

Humans are part of the environment and we need the environment to survive. As populations grow and life expectancies increase there needs to be a balance between the resources needed by humans and saving the environment. Sustainable manufacturing can play a big role in reducing pollution. They can do this by reducing waste, using manufacturing techniques that are eco-friendly and by using renewable energy. Burning of fossil fuels is one of the leading causes of air pollution. Using renewable energy to run factories will help a great deal in reducing air pollution.

Benefits to Businesses

1. Making eco-friendly products can help businesses attract customers who are concerned with the environment and also help save the environment. By using renewable energy. reducing waste and increasing productivity businesses can help play a key role in reducing pollution thereby helping the environment and keeping it safe for future generations. They can also recycle waste to further help the environment.

2. Reduce costs by investing in sustainable manufacturing techniques that can lower waste and reduce errors.

3. Use AI and digital twin technologies to create simulated models instead of using materials thereby further reducing costs and waste and speeding up product development. Refer to the below article for some ideas on how this can be implemented. Four ways AI will change design and manufacturing.

4. As new rules are enacted by Governments worldwide to reduce pollution companies can get a head start by focusing on sustainable marketing thereby getting Government approval faster and have a competitive advantage. This can help lower the cost of compliance.

5 techniques to implement sustainable manufacturing

Design products for sustainability

Products can be designed to be environmentally friendly as exemplified by the number of eco-friendly products on the market today. This can be done using recyclable raw materials that live another life and designing for durability.

Design for Disassembly

Design products that can be taken apart easily and be part of a reduce, reuse, recycle loop. This allows parts to be reused instead of ending up in a landfill. This process can reduce consumption of resources and pollution.

Reduce energy consumption of the product

Use components that are energy efficient in building products, build it to last longer so it doesn’t have to be replaced often thereby reducing the carbon footprint involved in building the product. Use raw materials that are bio degradable. Bio degradable materials don’t end up in landfills or in our rivers and oceans. Make your manufacturing facility energy efficient. Use packaging that is lightweight and recyclable.

Lightweighting

Make products with materials that weigh less thus decreasing the overall product weight. Use hollow components where possible for example. This technique is used in automotive and aerospace fields to build lighter cars, trucks and planes that are more energy efficient thereby reducing the carbon footprint.

Eliminate toxic materials

When designing the products eliminate toxic raw materials and use bio degradable or recyclable raw materials instead. This helps the environment by reducing pollution.

Agencies and resources

In the US it is the Environmental Protection Agency or EPA. In India it is the Ministry of Environment, Forest and Climate Change (MoEF) of India and in China it is the Ministry of Ecology and Environment.

EPA India (Aggregator of environmental information and organizations in India)

Conclusion

Sustainable manufacturing is not just a moral imperative; it’s a strategic imperative for businesses aiming for long-term success in a world grappling with environmental challenges. The examples highlighted above underscore the transformative potential of sustainable practices in diverse industries. By embracing sustainability as a guiding principle, manufacturers can pave the way towards a greener, more resilient future for generations to come. Read about the value. proposition of partnering with an EMS in our Ultimate Guide to Electronic Manufacturing Services.