Embracing the Next Phase: Podrain Electronics Steps into a New Era with Larger Facility

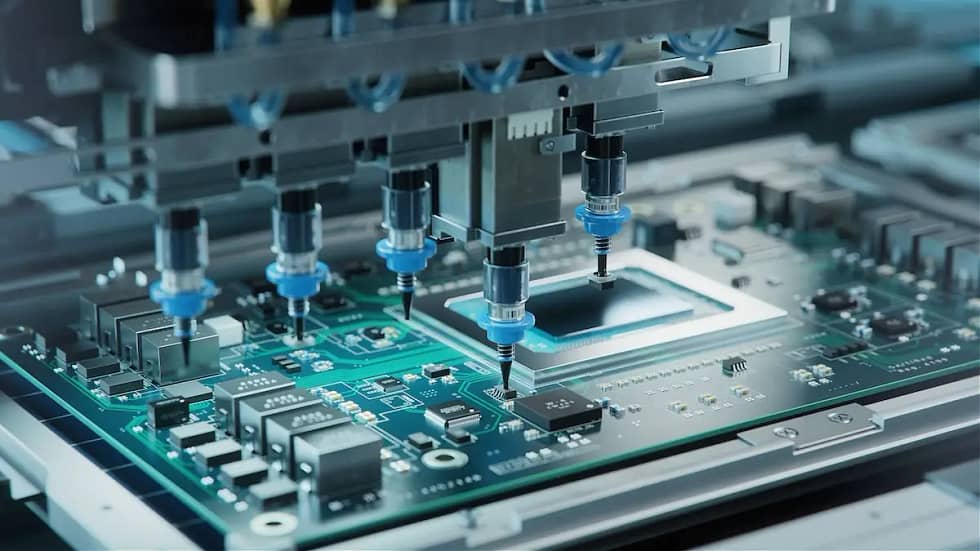

It’s with immense pride and excitement that we announce a significant milestone in the evolution of Podrain Electronics! We’ve officially moved into our new, expanded manufacturing facility marking a pivotal step in our journey from a nimble startup to a dynamic mid-sized player in the electronic manufacturing services landscape.

This move represents more than just an upgrade in physical space; it signifies the incredible growth and progress we’ve achieved. What began as a small, dedicated team with a vision has blossomed into a thriving company, and this new facility is a tangible symbol of that transformation. This expansion will empower us to:

- Embrace Mid-Size Capabilities: With significantly increased capacity, we’re now positioned to take on larger-scale projects and forge even stronger partnerships.

- Solidify Our Position: This new facility provides the infrastructure needed to solidify our standing as a reliable and capable mid-sized EMS provider.

- Invest in Continued Growth: The expanded space allows for strategic investments in advanced technologies and optimized workflows, paving the way for future innovation and expansion.

- Maintain Our Core Values at Scale: While growing, we remain committed to the agility, quality, and personalized service that defined our early days. This new facility allows us to scale our operations without compromising these core values.

This move to our new, larger factory is a testament to the hard work of our team, the trust of our clients, and the strength of our vision. We’re incredibly excited to embark on this next phase of our journey as a mid-sized company, and we look forward to the exciting opportunities that lie ahead. Join us as we continue to grow, innovate, and deliver exceptional electronic manufacturing services from our new home!