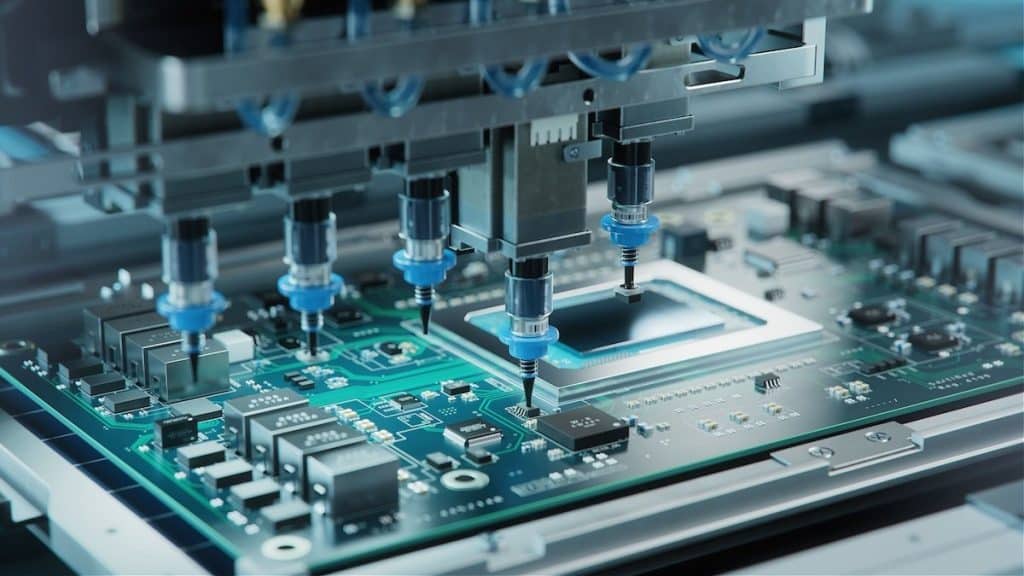

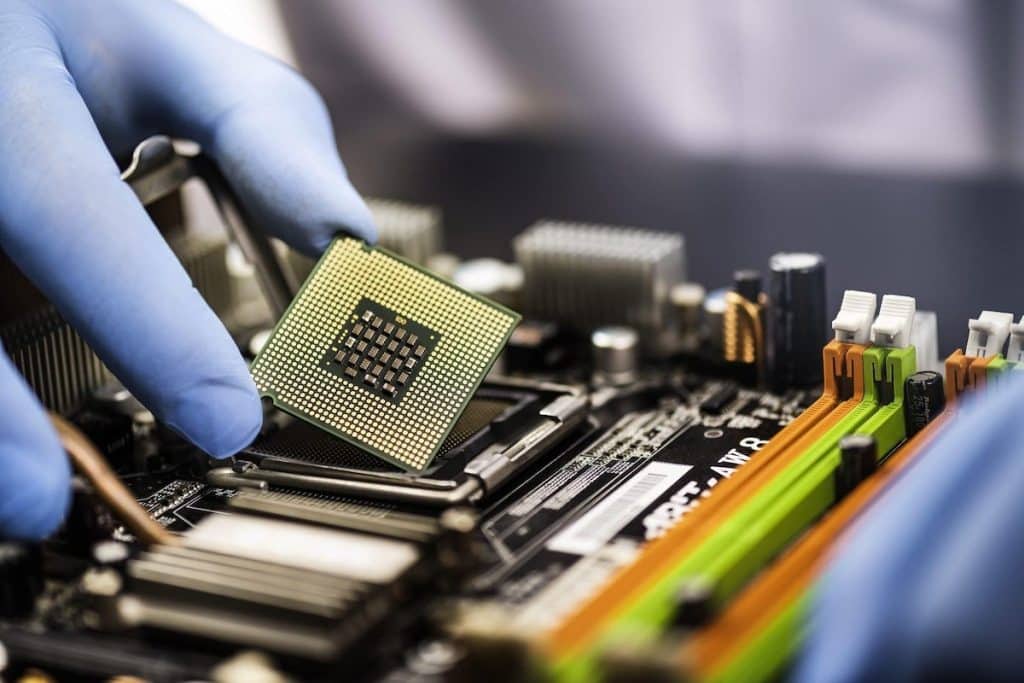

The electronics manufacturing services (EMS) industry in India has been growing rapidly over the past few years, and the growth rate is expected to continue in the future. According to a report by Research And Markets, the Indian EMS market was valued at USD 35.4 billion in 2020, and it is expected to grow at a compound annual growth rate (CAGR) of 21.8% from 2021 to 2026. Any growing industry also needs skilled people to aid its growth.

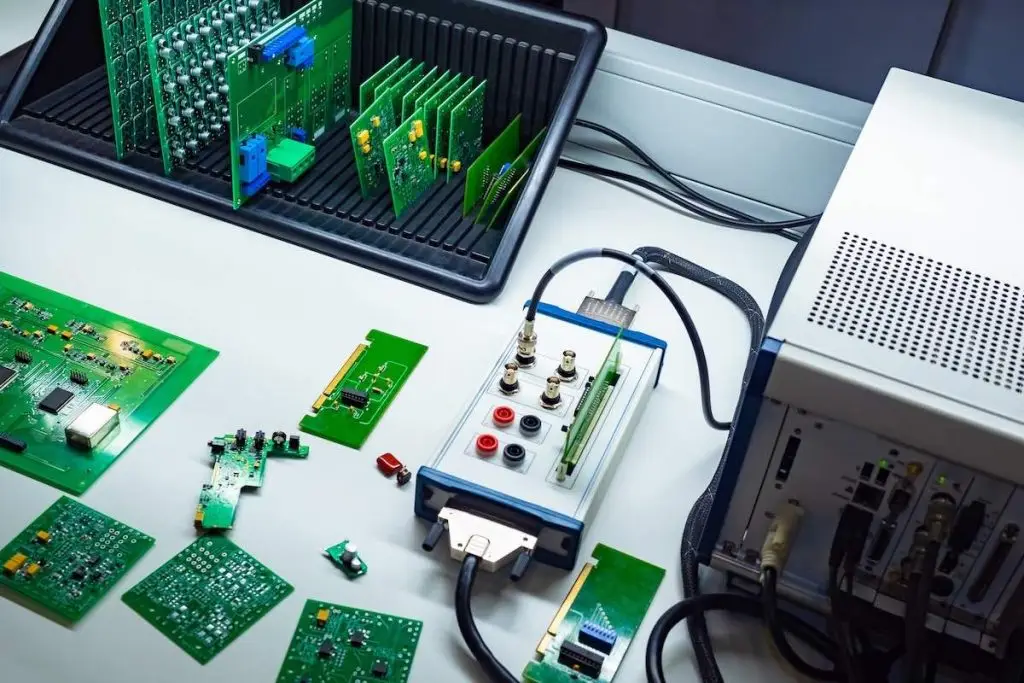

An electronics manufacturing services (EMS) company typically employs a range of professionals with different skills and expertise.

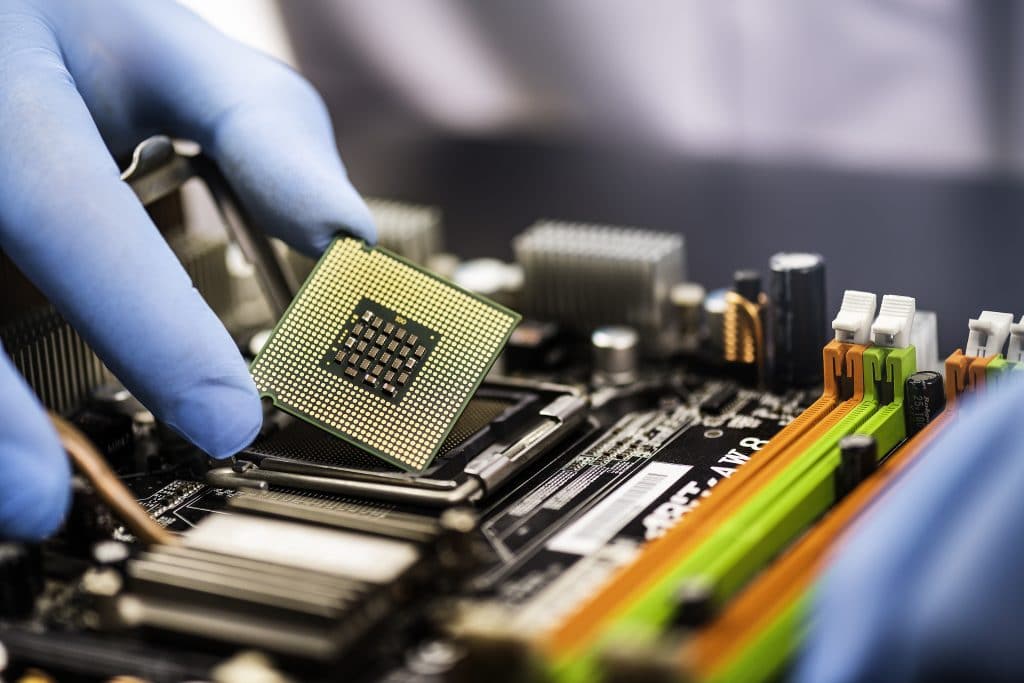

- Manufacturing engineers responsible for optimising the manufacturing process and designing production systems.

- Quality Control Engineers who inspect products, conduct tests and implement quality control procedures to ensure that products are manufactured to specifications.

- Supply Chain Managers and Logistics Co-ordinators who work with suppliers to ensure on time delivery and manage inventory levels for production schedules.

- Assemblers / Technicians: This role is the backbone of the industry and many who move on to quality control and supply chain management, make their start as assemblers / technicians.

Getting a start in this sunrise industry requires a combination of education and practical training. For students or even those who are mid-career, wondering what will help you, here are a few thing to consider:

- Get a Technical degree: This is the best option for students who are still planning their education. Pursuing a degree in electrical engineering, electronics engineering, or a related technical field can provide a strong foundation for a career in EMS. These degree programs typically cover topics such as circuit design, digital electronics, microcontrollers, and power electronics.

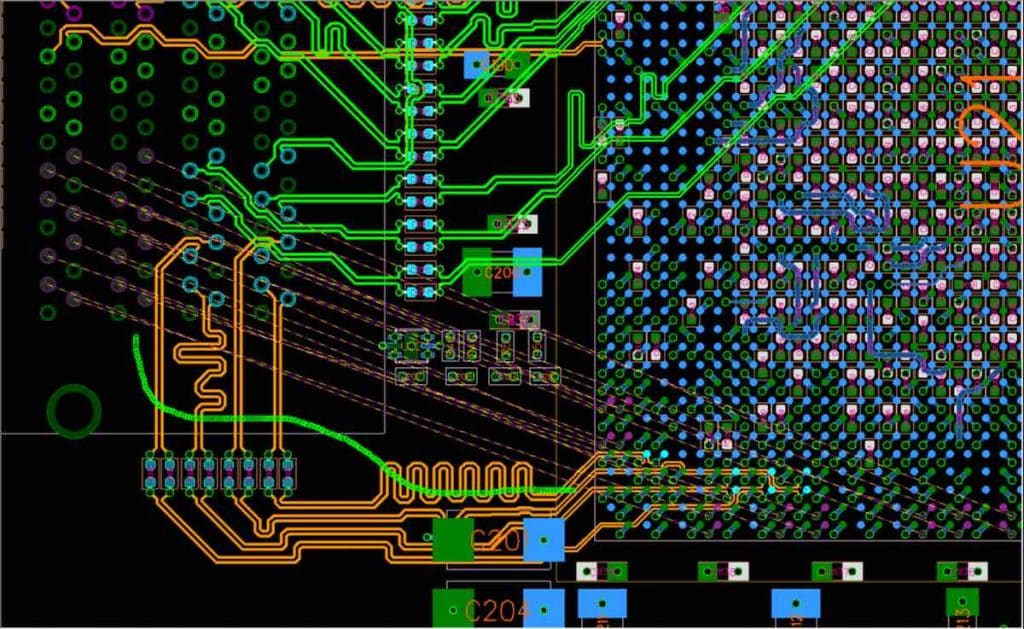

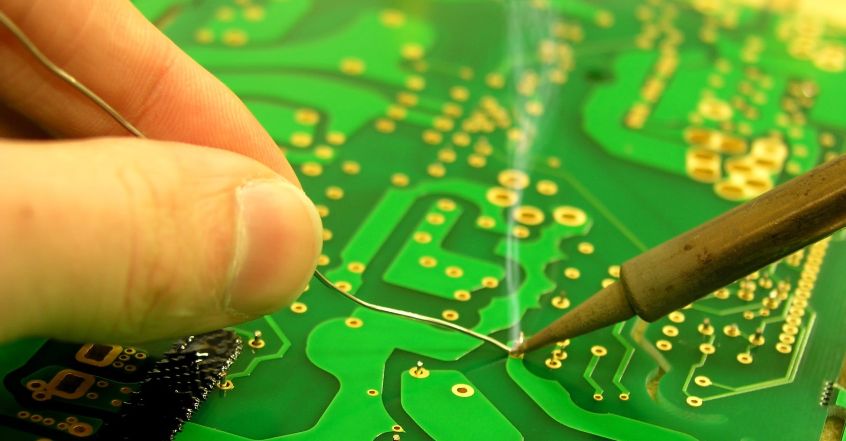

- Join a Vocational training program: Vocational training programs, such as those offered by ITI’s or trade specific orgalisations like Electronics Sector Skill Council, can provide hands-on training in electronics manufacturing. These programs may cover topics such as soldering, PCB assembly, and quality control. Vocational training programs can sometimes be regarded as less prestigious but there is no parallel to the practical learning they offer and their grounded and quick start to careers.

- Certifications: Obtaining industry certifications, such as IPC-A-610 (Acceptability of Electronic Assemblies) and IPC-J-STD-001 (Requirements for Soldered Electrical and Electronic Assemblies), can demonstrate expertise in specific areas of electronics manufacturing and can be very valuable.

- Internships or apprenticeships: Participating in an internship or apprenticeship program with an EMS company can provide valuable on-the-job training and help you gain practical experience in electronics manufacturing. Podrain has been offering paid internships since inception. Some of our interns go back to studying but many move on to working with us or other peers in the EMS industry

Overall, a combination of technical education, hands-on training, and industry certifications can help prepare you for a successful career in Electronics Manufacturing Services.

For more information on careers at Podrain write check our website and write to us as [email protected]

Note: Post generated with assistance from ChatGPT3